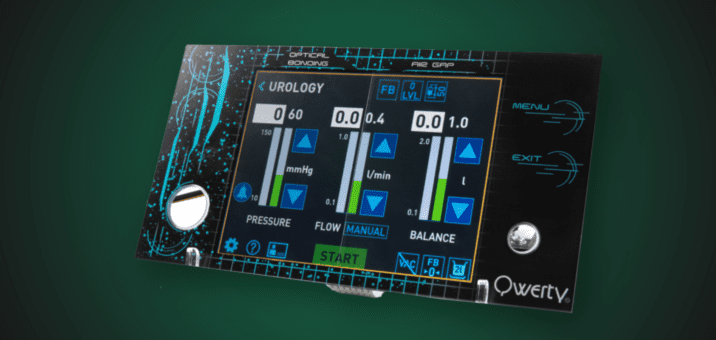

Touch panels accompany us everywhere – from medical devices to industrial control panels and military systems. With each project, the demands on their durability and image quality increase. The answer is optical bonding technology, which we at Qwerty use to produce panels that are extremely resistant to mechanical damage while offering excellent legibility in any lighting conditions.

Optical bonding is a process of permanently joining the layers of a touch panel, which eliminates air gaps between them. This seemingly simple method produces impressive results – it improves the optical performance of the display and significantly increases its durability. In this article, we will show how we use this technology in our projects and what specific benefits it brings to users.

What Is Optical Bonding?

Optical bonding is an advanced bonding method for optical elements that completely eliminates air gaps between touch panel layers. The process uses specially formulated optical adhesives to permanently bond the display, touch layer, and protective glass.

Traditional assembly methods leave microscopic gaps filled with air between the layers. These seemingly insignificant gaps considerably affect the performance of the panel – they cause light reflections, reduce image contrast, and weaken the mechanical structure. With optical bonding, we can fill these gaps with an adhesive with optical properties that match the other materials. The result? A monolith in which all layers work together to provide excellent image clarity and high impact resistance.

How Does Optical Bonding Work?

Optical bonding is a process in which precisely selected optical adhesives bond the individual layers of a touch panel into a single, cohesive whole. Two types of materials are used for this purpose: OCA (Optically Clear Adhesive) in the form of adhesive tapes and LOCA (Liquid Optically Clear Adhesive) in liquid form.

The bonding process begins with a thorough cleaning of the surface of all parts. With LOCAs, the liquid material is precisely dispensed onto the panel surface. OCAs are applied like an advanced adhesive tape – layer by layer. Each step requires extreme precision, as even the smallest contamination or air bubble can affect the optical performance of the entire device.

After the adhesive is applied, the curing process takes place by exposing the parts to UV light or elevated temperatures – the method depends on the type of material used and the intended use of the panel.

At this stage, the adhesive forms a transparent, durable layer that retains its properties throughout the life of the panel – it does not yellow, does not lose its transparency, and effectively protects the interior of the device from moisture and dirt.

The result of this precise operation is a touch panel with much better performance – more resistant to mechanical damage and offering excellent visibility of the displayed content even in challenging lighting conditions.

How Does Optical Bonding Improve Touch Panels?

The use of optical bonding significantly improves the performance of touch panels both in terms of image quality and mechanical strength. Compared to traditional assembly methods, this technology brings concrete improvements in many aspects of use.

Improved Image Quality

The optical parameters of the touch panel are fundamental to the comfort of its use. Optical bonding causes the following improvements:

- Reduction of glare – eliminating the layer of air between the screen and the panel significantly reduces reflections of external light, providing excellent readability even in bright sunlight.

- Higher quality of the displayed image – the bonding of layers increases contrast and color saturation, making the displayed content clearer and more detailed.

- Elimination of optical distortion – replacing the air layer with optical glue prevents the “fogging” effect, which can impair the visibility of the displayed content.

These improvements will be especially appreciated by users of devices operating in variable lighting conditions, where good screen visibility is of paramount importance.

Increased Durability and Resistance

Optical bonding does not only improve image quality – it can also significantly strengthen the panel design:

- Impact and vibration resistance – the integrated structure more effectively dissipates impact energy, protecting delicate electronic components.

- Protection against contamination – the lack of space between the layers eliminates the risk of dust and moisture getting inside the panel.

- Reinforced mechanical design – the combination of layers into a single unit increases resistance to deformation and surface damage.

The reinforced design significantly extends the life of the device and reduces the risk of malfunction.

Improved Operation Performance

Optical bonding improves not only durability but also the functionality of touch panels. Eliminating the layer of air between the touch surface and the display results in a more precise and natural response to touch. The panel responds faster and more accurately to the user’s commands, making the device more comfortable to use. In addition, reduced internal reflections ensure that the image remains clear regardless of the viewing angle.

Ability To Work in Difficult Conditions

Panels made with optical bonding technology perform well in the most demanding applications. Proper selection of adhesive materials ensures stable operation over a wide temperature range and UV resistance. This is particularly important for devices operating outdoors or in challenging industrial environments.

The sanitary aspect is also worth emphasizing – the smooth, gap-free surface is easy to clean and disinfect. This is an important advantage in the medical or food industries, where hygiene is a priority.

Optical Bonding – Proven Technology in Qwerty Products

At Qwerty, we have been using optical bonding for years as a proven method of manufacturing high-performance touch panels. This technology allows us to manufacture devices that meet the most stringent requirements – from medical panels, where precision of operation and ease of disinfection matter, to industrial systems operating in difficult environments.

Optical bonding is much more than a way of joining the layers of a panel – it is a comprehensive solution that improves image quality, increases mechanical durability, and enhances the device’s user experience. The elimination of air gaps between the layers results in better readability of the display, greater resistance to damage, and a more precise response to touch.

Go back

Go back  March 18 2025

March 18 2025