In industrial systems, every millisecond of equipment response time to operator commands counts. Membrane and foil keyboards, installed in control panels of CNC machines, production lines, and diagnostic devices, have to transmit signals to controllers immediately. Other than resistance to harsh operating conditions and mechanical strength, interface response time has become a critical parameter for determining safety and production efficiency.

Delays in signal transmission from the keyboard to the controller lead to quantifiable problems – from inaccurate CNC machining or production line disruption to increased risk of accidents during machine operation. Minimizing these delays requires specialized technical solutions and precise measurement methods.

In this article, we will analyze the sources of signal delays in membrane and foil keyboards, demonstrate ways to identify them and indicate what technology solutions can minimize them.

Design and Operating Principles of Membrane and Foil Keyboards

The process of generating and transmitting signals in membrane and foil keyboards relies on the precise cooperation between several layers of conductive and insulation materials. Understanding this multilayer design allows for a better understanding of the sources of potential delays in control signal transmission.

Design and Operation of Membrane Keyboards

At the heart of every membrane keyboard is a flexible layer with precision-formed spring domes under each key. When a key is pressed, the dome flexes and bridges two conductive traces, closing an electrical circuit. This generates a characteristic tactile confirmation for the operator and sends a signal to the control system.

The basic building blocks of a membrane keyboard are:

● An outer layer made of high-performance polyester to protect the keys against damage.

● Flexible membrane with spring domes made of specially selected material.

● Printed circuit layers with conductive traces.

● Insulating spacers to ensure optimal spacing between layers.

● Bottom layer with signal outputs.

The precise manufacturing and assembly of these layers ensures not only reliable operation but also immediate response to each keystroke.

Operating Principles of Foil Keyboards

Foil keyboards use thin layers of foil with electrical circuits. Instead of spring domes, foil keyboards use spacers to maintain appropriate spacing between the conductive layers. After the operator applies pressure, the top foil deforms, and the electric circuit closes at the point of contact.

The main components of a foil keyboard are:

● A transparent abrasion-resistant protective film.

● Top layer of foil with printed circuits.

● A spacer system that determines the activation point.

● A lower conductive layer with a matrix of contact points.

● Installation layer with electrical outputs.

Both types of keyboards, although different in design, must ensure precise and repeatable operation in harsh industrial environments. The accuracy of the manufacturing of each layer and the quality of the connections between them directly translates into the speed and reliability of control signal transmission.

What Are the Main Causes of Keyboard Lag?

In industrial control systems, latency between a keystroke and device response can have significant consequences. That’s why it’s so important to understand all the factors affecting the speed of signal transmission in membrane and foil keyboards. Our experience in manufacturing industrial interfaces has identified five main areas that generate potential delays.

Conductive Properties of Materials

Signal transmission time depends on the electrical resistance of the materials used. In large industrial keyboards, where conductive traces are long, even a small resistance can generate noticeable delays. Particularly important is the quality of the conductive paste used to print the circuits and its stability under various operating conditions.

The mechanical parameters of membranes and foils affect the closing speed of the electrical circuit. Materials that are too stiff increase the time between the keystroke and the moment when the conducting surfaces connect. Selecting the appropriate flexibility of these components optimizes both response time and operating comfort.

Complex industrial interfaces require extensive conduction trace layouts. This design can cause additional delays in signal analysis in the controller. When designing electrical systems, we look for a balance between functionality and simplicity of trace routing.

Impact of Electromagnetic Interference (EMI)

Industrial equipment generates strong electromagnetic fields, which can interfere with the transmission of signals from the keyboard to the controller. This leads to delays or erroneous readings. Stable response times can be maintained by using suitable shielding and optimized signal path routing.

Integration With Control Systems

Operating speed depends not only on the keyboard itself but also on the entire control system. The processor’s signal processing time and communication with actuators can cause additional delays. That is why we optimize our interfaces to work with various industrial systems.

What Is Signal Delay Diagnostics Based On?

To effectively minimize the response time of industrial keyboards, it is first necessary to accurately identify all sources of delay. Special diagnostic methods are used to measure and analyze the entire signal transmission process precisely – from the press of a key to the response of the control system.

Diagnostics using digital oscilloscopes and signal analyzers make it possible to measure delays to a microsecond. The device records the moment when a key is physically pressed and a signal appears in the control system. The measurement system also tracks transmission stability and detects potential interference that can increase interface response time.

Tests in Real Operating Conditions

Special test stations reproduce the typical operating conditions of industrial keyboards. The interfaces undergo tests at various levels of electromagnetic interference, with vibrations and under varying temperatures. Many hours of measurement cycles show how stable the response time remains during intensive operation.

Analysis of the properties of the materials used in keyboards makes it possible to predict their effect on signal transmission speed. The most important parameters to test are:

● Electrical conductivity of paste and traces.

● Elasticity of membranes and contact elements.

● Material resistance to aging and fatigue.

● Stability of parameters under different environmental conditions.

These comprehensive analyses and tests provide the data needed to optimize keyboard designs and select materials to ensure fast and reliable signal transmission in industrial applications.

How To Optimize Keyboard Response Time in Industrial Systems?

The response time of industrial keyboards can be significantly reduced by properly optimizing each signal path component. The technical solutions described below demonstrate how to achieve an immediate system response to operator commands.

Use of Advanced Conductive Materials

The use of high-quality conductive materials is the basis for high-speed signal transmission. Electrical traces made of high-purity silver or copper ensure minimal electrical resistance. In addition, special conductive pastes with noble metal nanoparticles provide stable electrical performance even under varying environmental conditions.

Precisely selected layer thicknesses in keyboard design directly affect signal speed. Thinner membranes and foils shorten the movement length of contact elements, which speeds up circuit closing time. At the same time, the design must maintain sufficient mechanical strength to guarantee reliability in industrial applications.

Electronic signal amplifiers, strategically placed in the keyboard circuits, compensate for losses on long conducting traces. Amplification ensures stable amplitude of control signals regardless of the complexity of the electrical system and operating conditions.

High-performance EMI filters protect control signals from the effects of electromagnetic fields. Advanced filtering circuitry eliminates noise and distortion that could lead to transmission delays or signal misinterpretation by the controller.

Modern industrial keyboards are often integrated with computer systems that analyze signals and generate responses. Updating firmware and optimizing processing algorithms can significantly improve response times.

Modern Technologies That Support Delay Minimization

Development in the field of electronics and novel materials is providing new opportunities to accelerate industrial interface responsiveness. Advances in technology make it possible not only to reduce signal transmission times but also to continuously monitor and optimize the performance of keyboards under manufacturing conditions.

The use of piezoelectric materials introduces a new quality to the design of foil keyboards. The active element generates an electrical signal as soon as pressure is detected, eliminating the delays associated with mechanical circuit closing. This technology is particularly suitable for systems that require an instant response, such as emergency shutdown systems or precision control of CNC machines.

Modern controllers use advanced microprocessor chips that analyze keyboard signals in real time. Intelligent adaptive algorithms automatically adjust the processing parameters to the current operating conditions, ensuring minimal response time even under strong electromagnetic interference or varying ambient temperature.

Integrating keyboards with the Industrial Internet of Things infrastructure makes it possible to monitor their performance constantly. Sensors embedded in the interface send data on response time and signal stability to a central analysis system. Based on this information, it is possible to automatically adjust the operating parameters of the keyboard, ensuring optimal performance under all conditions.

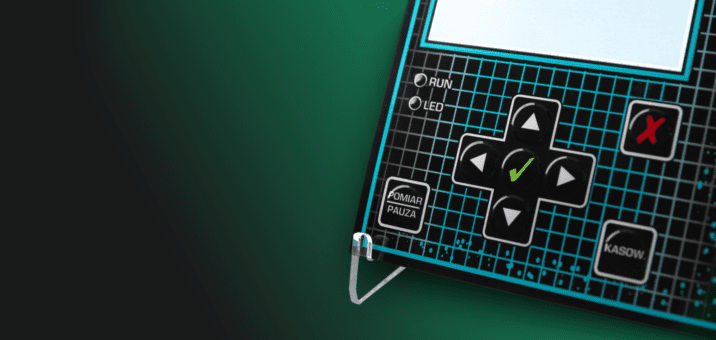

Foil and Membrane Keyboards With the Fastest Response Time – Reliable Solutions Made by Qwerty

Minimizing response times in membrane and foil keyboards requires a comprehensive approach. High-quality conductive materials, advanced electronics, and precision design shorten the signal path from the key to the controller. Effective interference protection and intelligent signal processing further speed up the interface. Combined with continuous performance monitoring, these solutions ensure that our keyboards respond instantly and reliably, even in the harshest industrial environments.

Our research laboratory designs membrane and foil keyboards that meet the highest industry standards. Each interface combines advanced materials technologies, precision electronics, and innovative design solutions. As a result, our keyboards not only respond instantly to operator commands but also guarantee the highest durability and reliability in the harshest operating conditions. Rigorous real-world tests confirm stable performance even after years of intensive use in aggressive industrial environments.

Go back

Go back  March 18 2025

March 18 2025