Minimizing Signal Delay in Membrane and Graphic Overlays Keypads for Industrial Systems

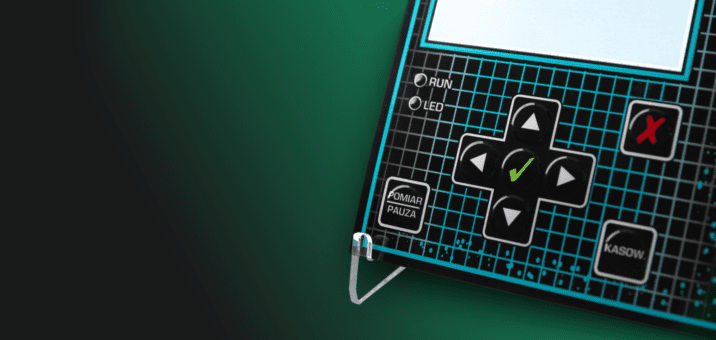

In industrial control systems, every millisecond of device response time matters. Membrane and graphic overlay keypads installed in CNC control panels, production lines, and diagnostic equipment must transmit signals to controllers instantly. In addition to durability and resistance to harsh environments, interface response time has become a critical parameter determining production safety and efficiency.

Signal transmission delays between keypad input and controller response can lead to real-world problems—from machining inaccuracies in CNC systems and production line disruptions to increased operator safety risks. Minimizing these delays requires advanced engineering solutions and precise diagnostic methods.

This article analyzes the sources of signal delay in membrane and graphic overlay keypads, explains how to identify them, and presents technological solutions that enable their minimization.

Design and Operating Principles of Membrane and Graphic Overlay Keypads

Signal generation and transmission in membrane and graphic overlay keypads rely on the precise interaction of multiple conductive and insulating layers. Understanding this layered structure helps identify potential sources of signal delay.

Membrane Keypad Construction and Operation

At the core of a membrane keypad is a flexible layer with precisely formed metal or polyester domes beneath each key. When pressed, the dome collapses and connects two conductive traces, closing the electrical circuit. This action provides tactile feedback and sends a signal to the control system.

Key structural components include:

- A durable polyester top layer for mechanical protection

- A flexible membrane layer with tactile domes

- Printed circuit layers with conductive traces

- Spacer layers ensuring optimal separation

- A bottom layer with signal outputs

Precise manufacturing and assembly ensure not only reliability but also immediate response to each key press.

Graphic Overlay Keypad Operation

Graphic overlay (foil) keypads use thin film layers with printed conductive circuits. Instead of tactile domes, spacer layers maintain separation between conductive surfaces. Operator pressure deforms the top layer, closing the circuit at the contact point.

Main components include:

- Abrasion-resistant protective overlay

- Upper printed circuit layer

- Spacer system defining actuation points

- Lower conductive layer with contact matrix

- Mounting layer with electrical outputs

Both technologies must ensure precise, repeatable operation under demanding industrial conditions. Layer accuracy and interconnection quality directly influence signal transmission speed and reliability.

Main Causes of Signal Delays

In industrial control systems, any delay between input and system response may have significant consequences. Based on extensive industrial interface development experience, five primary sources of delay can be identified.

Conductive Material Properties

Signal transmission time depends on the electrical resistance of conductive materials. In large industrial keypads with long conductive traces, even minor resistance can create measurable delays. The quality and environmental stability of conductive inks are critical.

Membrane or Film Quality

Mechanical properties affect the time required to close the electrical circuit. Excessively stiff materials increase the interval between key actuation and electrical contact. Proper elasticity ensures both fast response and user comfort.

Circuit Complexity

Complex interfaces require intricate trace layouts. This may introduce additional processing time within the controller. Electrical design must balance functionality with signal path efficiency.

Electromagnetic Interference (EMI)

Industrial environments generate strong electromagnetic fields that may distort or delay signal transmission. Proper shielding and optimized trace routing are essential for stable response times.

Control System Integration

Response speed depends not only on the keypad but also on controller processing speed and communication with actuators. Interfaces must be optimized for compatibility with industrial control architectures.

Signal Delay Diagnostics

Effective response time optimization begins with precise identification of delay sources.

Response Time Measurement

Digital oscilloscopes and signal analyzers measure delays with microsecond accuracy, capturing both physical actuation and signal detection by the controller. Transmission stability and noise disturbances are also analyzed.

Real-World Condition Testing

Specialized test benches simulate electromagnetic interference, vibration, and temperature fluctuations. Long-duration test cycles evaluate response stability during intensive operation.

Material Quality Analysis

Key evaluated parameters include:

- Electrical conductivity of traces and inks

- Elastic properties of membranes and contacts

- Aging and fatigue resistance

- Environmental stability

These analyses provide essential data for performance optimization.

Optimizing Keypad Response Time

Advanced Conductive Materials

High-purity silver or copper traces reduce electrical resistance. Nanoparticle-enhanced conductive inks ensure stable parameters under variable environmental conditions.

Reduced Layer Thickness

Thinner membranes shorten mechanical travel distance, accelerating circuit closure while maintaining structural integrity.

Signal Amplification

Strategically placed amplifiers compensate for voltage drops across long conductive paths, ensuring stable signal amplitude.

EMI Filtering

High-performance EMI filters eliminate noise and distortion that could delay signal processing.

Firmware Optimization

Optimized firmware and processing algorithms significantly reduce system-level latency in computer-integrated interfaces.

Advanced Technologies Supporting Delay Reduction

Piezoelectric Technology

Piezoelectric materials generate electrical signals immediately upon pressure detection, eliminating mechanical switching delay. This is particularly effective in emergency stops and precision CNC control systems.

Intelligent Controllers

Advanced microprocessors analyze input signals in real time. Adaptive algorithms adjust processing parameters dynamically, ensuring minimal latency even under heavy EMI or temperature variation.

IoT Integration

Industrial IoT connectivity enables continuous monitoring of response time and signal stability. Embedded sensors provide real-time data, allowing predictive adjustments for optimal performance.

Qwerty High-Speed Membrane and Graphic Overlay Keypads

Minimizing response time requires a comprehensive engineering approach. High-quality conductive materials, advanced electronics, optimized mechanical design, EMI protection, and intelligent signal processing collectively ensure ultra-fast and reliable performance.

At Qwerty, our R&D laboratory develops membrane and graphic overlay keypads that meet the highest industrial standards. Each interface integrates advanced material technologies, precision electronics, and innovative construction solutions. Rigorous real-world testing confirms stable performance even after years of operation in demanding industrial environments.

Go back

Go back  February 12 2026

February 12 2026