Industrial keyboards operate in harsh and demanding environments – from production halls exposed to strong vibrations, through cold storage facilities, to outdoor operator terminals exposed to rain and sunlight. Their reliable performance directly impacts production continuity and machine operation safety.

Ensuring high durability of these specialized interfaces requires a comprehensive testing process. Research laboratories, using precise measuring equipment, subject keyboards to a series of rigorous tests under controlled conditions. This makes it possible to verify their behavior in various scenarios – from extreme temperatures to long-term exposure to chemicals.

In this article, we share our knowledge about advanced durability testing methods for industrial keyboards. We will show how modern measurement technologies and rigorous testing procedures ensure reliability in demanding industrial environments.

Why Is Durability Testing of Industrial Keyboards Important?

The temperature ranges in which industrial keyboards operate vary significantly – from over 60°C in production halls to below -30°C in industrial freezers. Outdoor devices must withstand rain, UV radiation, and rapid temperature changes. In hospitals and the food industry, keyboards are regularly exposed to cleaning agents and disinfectants.

These environmental challenges are accompanied by intensive mechanical loads. Machine and production line operators use interfaces around the clock, often wearing work gloves. Buttons must remain fully functional even after hundreds of thousands of operating cycles. In heavy industry, devices are also exposed to constant vibrations and accidental impacts.

Failure of an industrial keyboard can have serious consequences. In machine control systems, it can lead to costly production downtime. In process installations, it may disrupt precise technological operations. Reliability is especially critical in safety systems, where an operator’s immediate response can prevent accidents or system failures.

For this reason, advanced durability testing forms the foundation of industrial keyboard development. Only rigorous verification of all parameters – from mechanical resistance to electrical stability under changing environmental conditions – ensures a product that meets high industrial requirements.

Types of Durability Tests for Industrial Keyboards

Modern testing laboratories subject industrial keyboards to rigorous trials that reflect real operating conditions. The testing process focuses on three main areas: environmental, chemical, and mechanical testing.

Environmental Durability Tests

Specialized laboratories conduct comprehensive tests simulating real-life operating conditions.

Thermal Resistance Testing

In climate chambers, keyboards undergo multi-stage testing in temperature ranges from -40°C to +80°C. Equipment records not only button performance stability but also structural integrity. Particular attention is paid to heating and cooling cycles that may cause mechanical deformation or weaken electrical connections.

Sealing and Moisture Resistance Verification

Testing systems evaluate keyboard performance in high-humidity conditions and during direct contact with water. Devices are exposed to water jets at various angles and pressures in accordance with international IP protection standards. The highest protection level, IP68, requires full functionality even after prolonged immersion.

Dust Resistance Testing

In specialized dust chambers, keyboards are exposed to industrial dust, sand, and other fine particles. Sensors monitor dust penetration and assess its impact on button mechanisms and electrical connections.

Mechanical Resistance Tests

Pressure Tests

Automated systems perform millions of keystroke cycles under varying force levels. Sensors measure activation force changes and surface wear, predicting long-term durability.

Impact Tests

Test rigs simulate impacts of varying intensity. Measurement systems detect visible damage as well as subtle structural deformations and electronic disruptions.

Vibration Tests

Vibration tables generate prolonged shocks of varying intensity, simulating industrial machinery and vehicle environments. Sensors monitor the stability of mechanical and electrical connections.

Chemical Resistance Tests

Industrial keyboards often come into contact with oils, lubricants, cleaning agents, solvents, and acids. In laboratory chambers, devices are exposed to these substances for extended periods. Tests assess not only surface condition but also durability of construction materials, protective coatings, seals, and key markings.

Technologies and Equipment Used in Durability Testing

Modern laboratories use advanced measurement systems:

- Environmental test chambers – simulate temperature, humidity, and atmospheric factors.

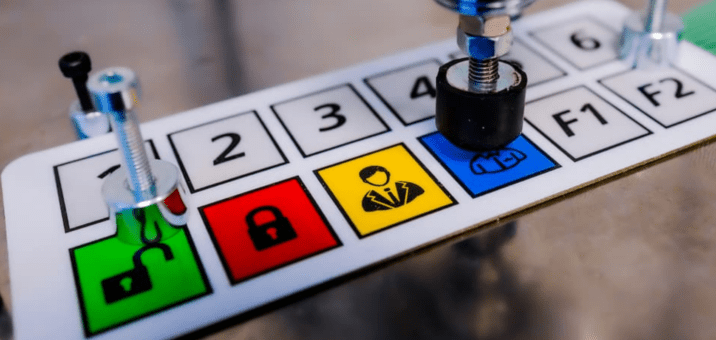

- Robotic pressure testers – perform hundreds of thousands of keystroke cycles.

- Thermal imaging analysis – identifies overheating areas and potential failure points.

How We Ensure Keyboard Durability at Qwerty

The Qwerty research laboratory, equipped with advanced measurement equipment, conducts rigorous durability testing of industrial keyboards. Our products undergo comprehensive environmental, mechanical, and chemical testing before reaching customers. Our procedures comply with international standards, including ISO and AQAP.

Years of experience have allowed us to develop proprietary durability verification methods. By combining specialized test chambers, automated testers, and precise diagnostic systems, we can accurately predict keyboard performance in various industrial conditions.

These extensive procedures translate into high reliability in everyday use – from production halls and outdoor installations to specialized applications.

Go back

Go back  February 12 2026

February 12 2026