Membrane keyboards are widely used in industry, medicine, and the military. Their reliable operation is of paramount importance for the safety and efficient functioning of many systems. However, moisture, frequent cleaning, and aggressive industrial environments can quickly damage them – primarily through corrosion of conductive components and deterioration of materials used in their construction.

Fortunately, modern technology offers effective methods of protecting membrane keyboards. Multilayer protective coatings, advanced hermetic sealing systems, and special seals can protect even the most sensitive components from harmful environmental factors.

In our research laboratory, we are systematically developing technologies to protect membrane keyboards from the destructive effects of moisture and corrosion. Tested in conditions far exceeding typical industry requirements, our protective solutions have proven themselves in thousands of industrial projects. The coating and hermetic sealing systems we developed not only protect electronic components from damage but also ensure the uninterrupted operation of interfaces in the most challenging conditions.

Why Is Moisture and Corrosion Protection Vital?

Precisely arranged conductive layers separated from each other by insulation materials play the main role in the construction of membrane keyboards. This multilayer design, while solid and reliable under normal conditions, becomes vulnerable to damage when exposed to moisture for long periods.

The effects of moisture can lead to serious functional problems. First of all, water, being an electrical conductor can form undesirable connections between conductive traces. As a result, keyboard malfunctions, random signals, or complete loss of functionality of some keys can occur.

In addition, prolonged exposure to moisture affects the structural integrity of the device. Water penetrating between the layers weakens the adhesive bonds, leading to delamination of the layers. As a result, the keyboard loses its mechanical stability, which manifests itself in inconsistent key operation or the complete disintegration of the layered structure.

Corrosion – The Silent Killer of Electronic Devices

A direct consequence of prolonged exposure to moisture is the advancing corrosion of keyboard metal components. This process, although often invisible to the naked eye, systematically destroys vital components of the device. At its core is a chemical reaction occurring between the metal components of the keyboard as well as moisture and oxygen from the environment.

The first sign of corrosion is the gradual deterioration of conductive properties. Oxidized conductive traces lose their ability to efficiently transmit electrical signals, which initially manifests itself as unstable key activation. Over time, the oxide layer becomes thick enough to completely block the flow of current in some areas of the keyboard.

Advancing corrosion also weakens the mechanical structure of the device. Oxidized components lose their durability, which can lead to cracking of conductive traces and delamination of the structure. As a result, the keyboard becomes susceptible to mechanical damage, and its repair often proves impossible.

Protective Coating – An Essential Element for Protecting Membrane Keyboards

Protective coatings are thin layers of materials that are applied to the surface of the keyboard to protect it from moisture, dust, and chemicals. There are several types of coatings which differ in properties and application.

Conformal coatings form a perfectly adherent protective layer that accurately reproduces the topography of the protected surface. Their primary advantage is versatile protection. They prevent moisture from penetrating sensitive electronic components while blocking dust and aggressive chemicals that could damage internal keyboard components. Thanks to their anti-corrosive properties, they significantly extend the life of metal components.

Conformal coatings are made of various materials, each with their unique properties. Silicones provide excellent flexibility and resistance to extreme temperatures. Polyurethanes are distinguished by their exceptional resistance to abrasion and mechanical damage. Epoxy coatings, on the other hand, form an extremely hard and hermetic protective barrier.

An important feature of this type of covering is transparency, which is particularly important for keyboards with prints or backlighting. Due to this feature, the protective properties can go hand in hand with maintaining the full functionality and aesthetics of the device.

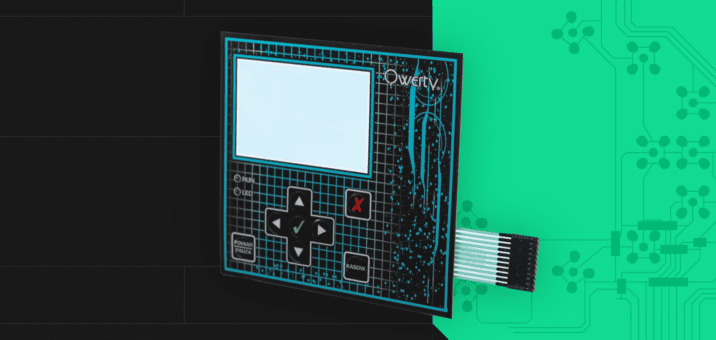

In the Qwerty laboratory, we have developed our unique conformal coating technology that ensures exceptional durability and uniformity of protection. Our many years of experience in the production of membrane keyboards allowed us to create a process that guarantees the highest quality coating while maintaining the full functionality of the device.

The unique properties of hydrophobic coatings are based on their ability to repel water actively, which makes the liquid droplets, instead of soaking into the surface, flow off it, leaving no traces.

At the microscopic level, the coatings form a special surface structure that reduces water adhesion. As a result, even in heavy rain or after liquid splashes, the keyboard surface remains practically dry. What’s more, the hydrophobic properties last for long periods of use, providing lasting protection for the device.

Hydrophobic coatings have particularly important applications in mobile devices that are constantly exposed to changing weather conditions. Industrial terminals, measuring devices, or equipment used in logistics must remain fully functional regardless of the weather. Hydrophobic protection allows them to work reliably both in the rain and in conditions of increased humidity.

The Qwerty team has optimized the process of applying hydrophobic coatings so they retain their properties even after years of intensive use. Our solutions have proven themselves in hundreds of industrial projects where keyboards are constantly exposed to water and aggressive cleaning substances.

Nanotechnology has brought new possibilities in the field of protecting membrane keyboards. Nanotechnology coatings work at a molecular level, creating an extremely thin but effective protective barrier just a few nanometers thick. Despite their microscopic thickness, they provide high resistance to moisture and aggressive chemicals.

The main advantage of these coatings is their near invisibility. The protective layer does not change the appearance or physical properties of the keyboard – the keys retain their sensitivity, and the markings remain clear. In harsh industrial environments, protected keyboards retain full functionality even with prolonged exposure to harmful external factors.

Hermetic Sealing – Protection at the Highest Level

Hermetic sealing is the most advanced method of protecting membrane keyboards. This comprehensive protection system involves creating an absolutely airtight barrier that effectively blocks moisture, dust, and other harmful agents from reaching sensitive electronic components.

In the process of designing hermetic keyboards, special attention is paid to the design of the case. Each component is precisely fitted and sealed, creating a uniform protective barrier. Special sealing systems protect all critical points – from cable openings to the connection points of individual structural components.

Effective hermetic sealing requires the use of specialized insulation materials. Modern silicone elastomers provide excellent sealing while remaining flexible even at extreme temperatures. High-performance plastics form a mechanical barrier, protecting the keyboard against external damage.

Filling the Interior With Protective Materials

In some solutions, the inside of the keyboard is filled with special protective materials. These advanced substances not only prevent condensation but also stabilize the temperature inside the device, increasing its reliability in changing environmental conditions.

Hermetic keyboards are rated according to the international IP (Ingress Protection) standard, which determines the level of protection against external factors:

● IP65 – provides full protection against dust and water jets from any direction.

● IP67 – guarantees moisture protection when immersed in water at a depth of 1 meter for 30 minutes.

● IP68 – offers the highest level of protection for continuous immersion in water at greater depths.

All Qwerty keyboards undergo rigorous testing in our laboratory, where we simulate extreme operating conditions. Each model undergoes hours of trials, testing and chemical resistance tests.

For Which Industries Is Moisture and Corrosion Resistance Particularly Important?

Effective protection against moisture and corrosion is an important requirement for membrane keyboards in many industries. Operating conditions in a variety of environments present specific challenges for protective systems – from regular contact with disinfectant fluids to exposure to changing weather conditions.

High humidity is a daily challenge for electronic equipment on factory floors, especially in the food industry, where regular washing and disinfection of production lines create an environment saturated with water vapor. Meat or dairy plants require keyboards that can withstand direct contact with water during cleaning. Under these conditions, watertight hermetic sealing and hydrophobic coatings become essential for maintaining production continuity.

Laboratories and Medical Facilities

In medical environments, keyboards are constantly exposed to water and disinfectant fluids. Frequent cleaning of work surfaces requires effective moisture protection. This is especially true in diagnostic laboratories, where accidental spills of samples or reagents cannot lead to equipment damage. Keyboards must be resistant not only to moisture but also to intensive disinfection procedures.

Outdoor equipment has to deal with rain, fog, and condensation. Payment terminals at car washes or equipment at swimming pools are constantly exposed to water splashes. Likewise, ticket vending machines or access systems at amusement parks must operate without fail,regardless of weather conditions. In these applications, the highest degree of moisture protection becomes crucial for long-term, issue-free operation.

The Future of Membrane Keyboard Protection Technology

The dynamic development of material technology and electronics is opening up new perspectives in the field of protecting membrane keyboards. Modern research is focused on developing increasingly sophisticated protective systems that not only secure the device but also actively respond to external risks.

Smart protective coatings are a particularly promising venue. These advanced materials are equipped with the ability to self-regenerate. If micro-damages occur, special chemical compounds contained in the coating automatically fill the resulting holes, restoring the consistency of the protective layer. This technology significantly extends the life of protection, eliminating the issue of gradual degradation of the coating.

Another groundbreaking solution is the integration of protective systems with Internet of Things technology. Built-in humidity and temperature sensors allow for continuous monitoring of keyboard conditions. This data, transmitted in real time to surveillance systems, enables rapid response to potential threats before damage occurs.

Qwerty Comprehensive Protection Solutions

We use comprehensive solutions and advanced technologies for moisture and corrosion protection in our membrane keyboards. We pay special attention to the ability to customize the level of protection to meet specific customer requirements. Whether you need a disinfection-proof medical keyboard or a fully airtight industrial terminal with an IP68 rating, we can meet your requirements.

Our research laboratory is constantly working on developing new protective technologies, focusing on innovative solutions such as intelligent self-regenerating coatings. This continuous technological evolution, combined with rigorous real-world testing, allows us to maintain our leadership in the field of high-quality industrial interfaces. By choosing our solutions, customers receive a product that meets the highest standards.

Go back

Go back  March 18 2025

March 18 2025